In our experience, when a company is deciding on a flooring system to use, it always comes down to Epoxy Resin or Polished Concrete.

Polished concrete has become increasingly popular due to the new and improved grinding machines and techniques that allow more attractive finishes to be created, whereas resin flooring has a wider variety of colours available and is quicker to put down.

These two flooring systems provide many of the same key benefits: they are both highly durable, light-reflective, chemical resistant, easy to clean, and can be anti-static whilst maintaining a shiny and sometimes seamless floor finish that can withstand constant foot traffic or machinery use within any facility. Both flooring systems also have impressive life spans, making them a great way for businesses to save costs over time.

When choosing the flooring system that is best for your space, the key factors that need to be considered are functionality, budget, aesthetics, and the type of finish you want to achieve.

Aesthetic

Polished Concrete

Polished concrete is created by using grinding machines to achieve a smooth and shiny surface, exposing as much or as little of the natural aggregate within the concrete as you choose.

The colour in the Polished Concrete is dependent on the mix of aggregates and sands from your local quarry, and this cannot be changed. You can add pigment or dye to the concrete mix, but this will only change the shade, not the colour. For example, adding black dye will give the concrete a dark grey shade. However, Renobuild does not recommend adding these as you cannot guarantee a definitive colour.

You can also create unique Feature Pieces suitable for every industry with Polished Concrete.

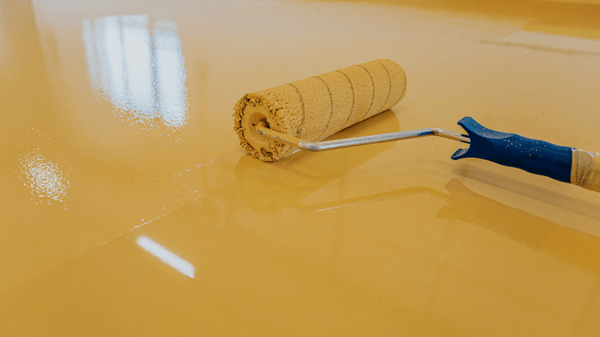

Epoxy Resin

If you are after a specific colour, then Epoxy Resin is the way to go.

Epoxy resin is a build up of layers consisting of primers and coatings or primers and self smoothing systems that can be applied over numerous types of surfaces, such as concrete, steel, or tiles, to create a durable and protective floor surface. There are a multitude of colour choices with Epoxy Resin, click here to see the full range.

Functionality

Polished Concrete

Polished Concrete floors are robust and hard-wearing, and not easily susceptible to tyre marking. They are effective at reflecting light and retaining heat, helping to lower costs over time. This flooring system also prevents a build-up of allergens such as dust and mould, leading to better indoor air quality. It is also low maintenance and easy to clean, making it hugely popular in the commercial sector.

Epoxy Resin

Resin floors are extremely durable and strong; they can handle heavy weight every day over a long period of time with ease. Resin is also able to withstand all environments, including being chemical, oil and stain, and slip resistant, and resistant to temperature changes and bacterial elements. Typically, a 3mm epoxy system will result in a surface strength of 60MPa.

This type of flooring is ideal for concealing and correcting imperfections due to its seamless and impervious qualities, making it perfect for industries where environmental issues or the ability to contain spills are crucial.

Preparation

Polished Concrete

The technicalities of how to proceed can range depending on the type of flooring already in place. Once removed, our team at Renobuild will inspect the floor in order to see what substrate is underneath. This allows us to assess the amount of work involved in preparing the floor for laying the new flooring system.

In a new building there would be less floor preparation, however Polished Concrete would still need to be laid correctly before it is polished. You can watch our video or read our blog to see our expert tips on how concrete should be laid for polishing.

With existing floors, there is some work that needs to be completed prior to polishing. It is vital the existing concrete is laid and finished correctly; smaller problems like cracks or chunks missing can be repaired, but if the substrate is too far gone it may not be possible to polish at all. In these cases, we would recommend using an overlay system.

Another key factor to consider is that during the grinding process up to 5mm can be taken off the concrete, so it is essential to make sure there is enough laid down to begin with.

The Renobuild team are on-hand to ensure the concrete laying process is done correctly for polishing – whether we complete the process ourselves, or liaise with your builder.